NANO WORLD

Wednesday, July 27, 2011

Research update: New way to store sun's heat

Supercapacitor-VinaTech - Power assist / 1.5F to 400F for UPS, Solar, AMR:

Storing the sun’s heat in chemical form — rather than converting it to electricity or storing the heat itself in a heavily insulated container — has significant advantages, since in principle the chemical material can be stored for long periods of time without losing any of its stored energy. The problem with that approach has been that until now the chemicals needed to perform this conversion and storage either degraded within a few cycles, or included the element ruthenium, which is rare and expensive.

Last year, MIT associate professor Jeffrey Grossman and four co-authors figured out exactly how fulvalene diruthenium — known to scientists as the best chemical for reversibly storing solar energy, since it did not degrade — was able to accomplish this feat. Grossman said at the time that better understanding this process could make it easier to search for other compounds, made of abundant and inexpensive materials, which could be used in the same way.

Now, he and postdoc Alexie Kolpak have succeeded in doing just that. A paper describing their new findings has just been published online in the journal Nano Letters, and will appear in print in a forthcoming issue.

The new material found by Grossman and Kolpak is made using carbon nanotubes, tiny tubular structures of pure carbon, in combination with a compound called azobenzene. The resulting molecules, produced using nanoscale templates to shape and constrain their physical structure, gain “new properties that aren’t available” in the separate materials, says Grossman, the Carl Richard Soderberg Associate Professor of Power Engineering.

Not only is this new chemical system less expensive than the earlier ruthenium-containing compound, but it also is vastly more efficient at storing energy in a given amount of space — about 10,000 times higher in volumetric energy density, Kolpak says — making its energy density comparable to lithium-ion batteries. By using nanofabrication methods, “you can control [the molecules’] interactions, increasing the amount of energy they can store and the length of time for which they can store it — and most importantly, you can control both independently,” she says.

Synthesis equipment - Only compact synthesizer allowing synthesis via solid, solution phase

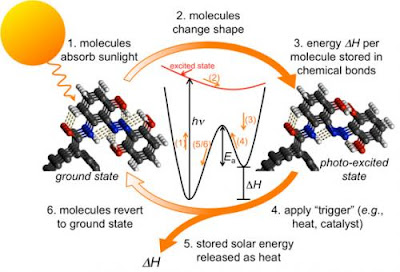

Thermo-chemical storage of solar energy uses a molecule whose structure changes when exposed to sunlight, and can remain stable in that form indefinitely. Then, when nudged by a stimulus — a catalyst, a small temperature change, a flash of light — it can quickly snap back to its other form, releasing its stored energy in a burst of heat. Grossman describes it as creating a rechargeable heat battery with a long shelf life, like a conventional battery

One of the great advantages of the new approach to harnessing solar energy, Grossman says, is that it simplifies the process by combining energy harvesting and storage into a single step. “You’ve got a material that both converts and stores energy,” he says. “It’s robust, it doesn’t degrade, and it’s cheap.” One limitation, however, is that while this process is useful for heating applications, to produce electricity would require another conversion step, using thermoelectric devices or producing steam to run a generator.

While the new work shows the energy-storage capability of a specific type of molecule — azobenzene-functionalized carbon nanotubes — Grossman says the way the material was designed involves “a general concept that can be applied to many new materials.” Many of these have already been synthesized by other researchers for different applications, and would simply need to have their properties fine-tuned for solar thermal storage.

The key to controlling solar thermal storage is an energy barrier separating the two stable states the molecule can adopt; the detailed understanding of that barrier was central to Grossman’s earlier research on fulvalene dirunthenium, accounting for its long-term stability. Too low a barrier, and the molecule would return too easily to its “uncharged” state, failing to store energy for long periods; if the barrier were too high, it would not be able to easily release its energy when needed. “The barrier has to be optimized,” Grossman says.

Already, the team is “very actively looking at a range of new materials,” he says. While they have already identified the one very promising material described in this paper, he says, “I see this as the tip of the iceberg. We’re pretty jazzed up about it.”

Yosuke Kanai, assistant professor of chemistry at the University of North Carolina at Chapel Hill, says “the idea of reversibly storing solar energy in chemical bonds is gaining a lot of attention these days. The novelty of this work is how these authors have shown that the energy density can be significantly increased by using carbon nanotubes as nanoscale templates. This innovative idea also opens up an interesting avenue for tailoring already-known photoactive molecules for solar thermal fuels and storage in general.”

Tuesday, July 26, 2011

Korg Nano Series

While big may have its advantages, it’s not necessarily clever when space is at a premium, or if compactness and portability are of importance. Korg’s dinky Nano control surfaces have been designed very much with laptop musicians in mind, although that’s not to say they wouldn’t be eminently useful in a larger studio setup.

There are three controllers available in the series: the Nano Key, the Nano Control and the Nano Pad. Imagine taking an axe to a larger MIDI keyboard controller and hacking it into three separate parts, consisting of the keyboard, the knobs and sliders, and the drum-trigger pads. Hey presto, you’ve got the Nanos, which are very neat, very small and, it has to be said, desperately cute! Each controller measures 320 x 83 millimeters and is around 15mm thick. They can be used individually or all at the same time, assuming you have the USB ports to spare. No additional power supplies are needed, as the units are USB bus powered, which keeps the cabling to a minimum — just the way we like it. A USB to mini-USB cable is helpfully supplied with each unit. If you need to connect the Nanos via a USB hub, it should be of the powered variety, otherwise connections must be made directly to the computer’s USB ports. The Nanos’ mini-USB sockets are sensibly mounted on the ends of the units, so two or more Nanos can be positioned one above the other. Construction is almost entirely of plastic, and while the units feel solid enough for their size, I’d be wary of getting too carried away in the heat of the moment, especially in the case of the Nano Pad, which is likely to receive many severe poundings during its lifetime. If you’re tempted to use drumsticks, just make sure your aim is good!

Nano Key

The Control Editor, showing the Nano Control settings. These pages make it simple to adjust and save each Nano’s parameters, although you may have to restart your DAW to implement changes.

The simplest of the three units, the Nano Key is a 25-note miniature keyboard spanning two octaves from C to C. The velocity sensitive keys are rather like inflated rectangular calculator buttons, with a choice of three velocity curves and a fixed velocity option, as well as a transpose facility covering plus or minus 12 semitones. The angle at which keys are pressed is fairly crucial, and misfires are common owing to the nature of the beast. Similarly, judging velocity accurately can be a little hit-and-miss, but you do get used to these foibles with a little practice.

While its size obviously precludes it from accommodating any form of continuous pitch and modulation wheels or levers, Korg have compromised by employing two buttons for pitch-bend and modulation — rather reminiscent of those found on the vintage ARP Odyssey analogue synth. Curiously absent from the Mod button parameters are attack and release time — the modulation jumps to its programmed values the instant you press or release the Mod button. The Pitch Up and Pitch Down buttons activate pitch-bend, and in this case you can specify the speed at which the pitch-bend occurs. Above these are Octave Up and Octave Down buttons (on the review model, the Octave Up button is erroneously labelled Pitch Up) providing a total range of nine octaves, with LEDs indicating the currently selected octave. Impressive-sounding virtuoso passages can be performed quite effortlessly by deftly flicking through the octaves while playing a fast phrase — all without changing your position on the keyboard!

Finally, the CC Mode button transforms the keyboard into 25 MIDI controller switches, each with its own CC number and on/off values. Like the Mod button, these switches transmit their values instantly, with no attack or release time option. Each key can be set to function momentarily or to toggle on/off with alternate presses, and each key can also be disabled from sending controller data.

Nano Pad

Many people are used to programming drums on velocity-sensitive finger pads — a method pioneered by the infamous Linn 9000 drum machine, eventually popularized by the Akai MPC series, and subsequently adopted by other drum machines. The Nano Pad’s trigger pads respond surprisingly accurately to playing velocity; all they fail to do is light up when you hit them! There is a choice of three velocity curves and fixed velocity, which apply globally to all pads. Each pad can send up to either eight simultaneous notes or eight simultaneous MIDI controller messages. Each of those eight control messages can have its own on and off values. Like the Nano Key, there are no attack and release time parameters for the pads’ controller data. Pads can either transmit on a single global MIDI channel or on independent channels, their behavior is either momentary or ‘toggle’, and any Pad can be disabled altogether.

Supplementing the trigger pads is the X-Y pad. A choice of pitch-bend or any CC number can be assigned to either axis, in positive or negative polarity. The X-Y pad also has an optional Touch/Release mode, whereby a third MIDI controller can be activated whenever the pad is touched. The on/off values and attack/release time of this third controller can be specified in the Control Editor.

The X-Y pad can also work in tandem with selected trigger pads to produce rolls or flams: activate the Roll button, press and hold a trigger key, and move your finger around the X-Y pad. Movement on the ‘X’ axis (sideways) varies the speed of the roll or flam, while the ‘Y’ axis (up/down) varies the note velocity. Moving your finger around in a circle while rolling produces dizzying results that would be almost impossible to program in any other way! In the case of flams, the X-Y pad must be touched before hitting a trigger pad — the velocity (‘Y’ axis) alters the volume of the second strike. Finally, the Hold button acts like a sustain pedal for the X-Y pad, retaining the most recent roll-speed and velocity values from when the pad was released.

The Nano Pad was the only one of the three units that exhibited any sort of fault: in this case, it continually insisted on killing Sonar’s audio engine every few minutes, even when the unit was not being played. Unless the Nano Pad hardware itself is software up datable, this behavior may not be correctable. It would be interesting to know if other DAWs are similarly affected.

Nano Control

The mini-USB port is the only connection found on each Nano. It should also give you an idea of just how small they are.

This, for me, is the pick of the bunch. Having used a Roland A50 as my main keyboard for the last 20 years, I find the Nano Control an excellent means of squeezing some extra useful life out of the old workhorse. This little gem offers a generous complement of nine sliders, nine knobs, 18 buttons and a set of DAW transport controls thrown in for good measure. I’ve experienced a number of ‘ultimate’ MIDI keyboard controllers of late and, quite frankly, the Nano Control knocks most of them into a cocked hat in the knob, slider and button department.

My initial expectation was that the knobs and buttons would feel cheap and scratchy, but they don’t. They have a pleasing, ‘oily’ smoothness, and the buttons feel reassuringly positive to the touch. When set to transmit CC messages, the Nano Control buttons enjoy the additional luxury of independent attack and release times, ranging from instantaneous response up to a maximum of 10 seconds — very useful for accurately timed filter sweeps, fade-outs, effect modulations and other precision gymnastics. Each of the buttons can be either momentary or toggle.

The six transport buttons are used to remotely control the transport functions of compatible software and devices, and can be assigned to transmit either MMC commands or MIDI controllers, according to the requirements of the receiving device. Although Sonar does not respond to these transport buttons by default, its transport functions can be programmed to react to external hardware controllers using either Sonar’s proprietary Active Controller Technology (ACT) or its in-built Control Surface plug-in. I opted for the latter method using the Cakewalk Generic Surface, and Sonar’s transport controls could then successfully be made to respond to the Nano Control.

Conclusion

Although Nanos can be purchased individually, being able to use any combination of the three simultaneously makes the complete suite particularly attractive. Three people can easily perform at once — one playing notes on the Nano Key and another playing drums on the Nano Pad, while a willing assistant mashes up the mix on the Nano Control. This flexible approach could well inspire some spontaneous, Fame-style ‘let’s do the show right here in the orphanage’ moments.

If you’re somewhere on the north face of the Eiger and can’t use a powered USB hub, or if you’re simply short on USB connections, no problem: just connect one Nano at a time. When you’re done with the first, simply unplug it and swap it for another — one of the great benefits of being hot-pluggable.

On a less Utopian note, the problems associated with auditioning edits proved to be a real test of patience, and the Nano Pad’s Sonar audio-engine serial-killer tendencies would be a problem from a personal point of view. Nevertheless, the Nanos are fun, portable and more powerful than their tiny bodies would suggest. The best bit is the cost: if you shop around, you can pick up each of these units for an amazingly low price. How could anyone resist? 0

There are three controllers available in the series: the Nano Key, the Nano Control and the Nano Pad. Imagine taking an axe to a larger MIDI keyboard controller and hacking it into three separate parts, consisting of the keyboard, the knobs and sliders, and the drum-trigger pads. Hey presto, you’ve got the Nanos, which are very neat, very small and, it has to be said, desperately cute! Each controller measures 320 x 83 millimeters and is around 15mm thick. They can be used individually or all at the same time, assuming you have the USB ports to spare. No additional power supplies are needed, as the units are USB bus powered, which keeps the cabling to a minimum — just the way we like it. A USB to mini-USB cable is helpfully supplied with each unit. If you need to connect the Nanos via a USB hub, it should be of the powered variety, otherwise connections must be made directly to the computer’s USB ports. The Nanos’ mini-USB sockets are sensibly mounted on the ends of the units, so two or more Nanos can be positioned one above the other. Construction is almost entirely of plastic, and while the units feel solid enough for their size, I’d be wary of getting too carried away in the heat of the moment, especially in the case of the Nano Pad, which is likely to receive many severe poundings during its lifetime. If you’re tempted to use drumsticks, just make sure your aim is good!

Nano Key

The Control Editor, showing the Nano Control settings. These pages make it simple to adjust and save each Nano’s parameters, although you may have to restart your DAW to implement changes.

The simplest of the three units, the Nano Key is a 25-note miniature keyboard spanning two octaves from C to C. The velocity sensitive keys are rather like inflated rectangular calculator buttons, with a choice of three velocity curves and a fixed velocity option, as well as a transpose facility covering plus or minus 12 semitones. The angle at which keys are pressed is fairly crucial, and misfires are common owing to the nature of the beast. Similarly, judging velocity accurately can be a little hit-and-miss, but you do get used to these foibles with a little practice.

While its size obviously precludes it from accommodating any form of continuous pitch and modulation wheels or levers, Korg have compromised by employing two buttons for pitch-bend and modulation — rather reminiscent of those found on the vintage ARP Odyssey analogue synth. Curiously absent from the Mod button parameters are attack and release time — the modulation jumps to its programmed values the instant you press or release the Mod button. The Pitch Up and Pitch Down buttons activate pitch-bend, and in this case you can specify the speed at which the pitch-bend occurs. Above these are Octave Up and Octave Down buttons (on the review model, the Octave Up button is erroneously labelled Pitch Up) providing a total range of nine octaves, with LEDs indicating the currently selected octave. Impressive-sounding virtuoso passages can be performed quite effortlessly by deftly flicking through the octaves while playing a fast phrase — all without changing your position on the keyboard!

Finally, the CC Mode button transforms the keyboard into 25 MIDI controller switches, each with its own CC number and on/off values. Like the Mod button, these switches transmit their values instantly, with no attack or release time option. Each key can be set to function momentarily or to toggle on/off with alternate presses, and each key can also be disabled from sending controller data.

Nano Pad

Many people are used to programming drums on velocity-sensitive finger pads — a method pioneered by the infamous Linn 9000 drum machine, eventually popularized by the Akai MPC series, and subsequently adopted by other drum machines. The Nano Pad’s trigger pads respond surprisingly accurately to playing velocity; all they fail to do is light up when you hit them! There is a choice of three velocity curves and fixed velocity, which apply globally to all pads. Each pad can send up to either eight simultaneous notes or eight simultaneous MIDI controller messages. Each of those eight control messages can have its own on and off values. Like the Nano Key, there are no attack and release time parameters for the pads’ controller data. Pads can either transmit on a single global MIDI channel or on independent channels, their behavior is either momentary or ‘toggle’, and any Pad can be disabled altogether.

Supplementing the trigger pads is the X-Y pad. A choice of pitch-bend or any CC number can be assigned to either axis, in positive or negative polarity. The X-Y pad also has an optional Touch/Release mode, whereby a third MIDI controller can be activated whenever the pad is touched. The on/off values and attack/release time of this third controller can be specified in the Control Editor.

The X-Y pad can also work in tandem with selected trigger pads to produce rolls or flams: activate the Roll button, press and hold a trigger key, and move your finger around the X-Y pad. Movement on the ‘X’ axis (sideways) varies the speed of the roll or flam, while the ‘Y’ axis (up/down) varies the note velocity. Moving your finger around in a circle while rolling produces dizzying results that would be almost impossible to program in any other way! In the case of flams, the X-Y pad must be touched before hitting a trigger pad — the velocity (‘Y’ axis) alters the volume of the second strike. Finally, the Hold button acts like a sustain pedal for the X-Y pad, retaining the most recent roll-speed and velocity values from when the pad was released.

The Nano Pad was the only one of the three units that exhibited any sort of fault: in this case, it continually insisted on killing Sonar’s audio engine every few minutes, even when the unit was not being played. Unless the Nano Pad hardware itself is software up datable, this behavior may not be correctable. It would be interesting to know if other DAWs are similarly affected.

Nano Control

The mini-USB port is the only connection found on each Nano. It should also give you an idea of just how small they are.

This, for me, is the pick of the bunch. Having used a Roland A50 as my main keyboard for the last 20 years, I find the Nano Control an excellent means of squeezing some extra useful life out of the old workhorse. This little gem offers a generous complement of nine sliders, nine knobs, 18 buttons and a set of DAW transport controls thrown in for good measure. I’ve experienced a number of ‘ultimate’ MIDI keyboard controllers of late and, quite frankly, the Nano Control knocks most of them into a cocked hat in the knob, slider and button department.

My initial expectation was that the knobs and buttons would feel cheap and scratchy, but they don’t. They have a pleasing, ‘oily’ smoothness, and the buttons feel reassuringly positive to the touch. When set to transmit CC messages, the Nano Control buttons enjoy the additional luxury of independent attack and release times, ranging from instantaneous response up to a maximum of 10 seconds — very useful for accurately timed filter sweeps, fade-outs, effect modulations and other precision gymnastics. Each of the buttons can be either momentary or toggle.

The six transport buttons are used to remotely control the transport functions of compatible software and devices, and can be assigned to transmit either MMC commands or MIDI controllers, according to the requirements of the receiving device. Although Sonar does not respond to these transport buttons by default, its transport functions can be programmed to react to external hardware controllers using either Sonar’s proprietary Active Controller Technology (ACT) or its in-built Control Surface plug-in. I opted for the latter method using the Cakewalk Generic Surface, and Sonar’s transport controls could then successfully be made to respond to the Nano Control.

Conclusion

Although Nanos can be purchased individually, being able to use any combination of the three simultaneously makes the complete suite particularly attractive. Three people can easily perform at once — one playing notes on the Nano Key and another playing drums on the Nano Pad, while a willing assistant mashes up the mix on the Nano Control. This flexible approach could well inspire some spontaneous, Fame-style ‘let’s do the show right here in the orphanage’ moments.

If you’re somewhere on the north face of the Eiger and can’t use a powered USB hub, or if you’re simply short on USB connections, no problem: just connect one Nano at a time. When you’re done with the first, simply unplug it and swap it for another — one of the great benefits of being hot-pluggable.

On a less Utopian note, the problems associated with auditioning edits proved to be a real test of patience, and the Nano Pad’s Sonar audio-engine serial-killer tendencies would be a problem from a personal point of view. Nevertheless, the Nanos are fun, portable and more powerful than their tiny bodies would suggest. The best bit is the cost: if you shop around, you can pick up each of these units for an amazingly low price. How could anyone resist? 0

Avnet Nano-ITX/Spartan-6 FPGA Development Kit

Avnet Electronics Marketing introduced the Nano-ITX/Spartan-6 FPGA Development Kit, which is based on the Intel Atom E640 Processor and Xilinx Spartan-6 FPGA. The kit features the Emerson Network Power Nano-ITX motherboard, Intel Atom processor E640, Spartan-6 FPGA PCI Express (PCIe) daughter card, and reference design. The Nano-ITX/Spartan-6 FPGA Development Kit is available now for $1,695. The Nano-ITX/Spartan-6 FPGA Development Kit is ideal for image processing, human machine interface (HMI), machine control, and medical applications applications.

Nano-ITX/Spartan-6 FPGA Development Kit Features

Avnet Electronics Marketing Nano-ITX/Spartan-6 FPGA Development Kit

Emerson Nano-ITX-315 motherboard

1 GHz Intel Atom E640 processor

Xilinx Spartan-6 FPGA PCIe card

PCIe x1 edge connector

PCIe interfaces directly to the Intel Atom processor

Xilinx Spartan-6 XC6SLX75T-3FGG676C FPGA

Eight 3.125 Gbps GTP on-chip transceivers

Low pin count (LPC) FPGA Mezzanine Card (FMC) connector for expansion modules

General purpose input/output (GPIO) connector

Two independent memory banks of DDR3 SDRAM, each with 128MB of storage

Maxim SHA-1 EEPROM for FPGA design security

1 GB DDR2 memory

Standard PC peripherals

Small 120 mm x 120 mm format

10/100 Ethernet PHY

20 x 2, 0.1-inch user I/O header (MXP)

Two 2 x 6 PMOD expansion ports

128 Mb Multi-I/O SPI Flash

32 MB parallel Flash memory

USB-to-UART port

Four LEDs

4-bit DIP switch

Four push-button switches

In-depth step-by-step tutorial: Developing a Microsoft Windows Embedded Standard 7 based system with a custom FPGA peripheral

Terasic DE0-Nano FPGA Development Board

Terasic Technologies introduced the DE0-Nano FPGA development and education board for prototyping circuit designs. The DE0-Nano board features an Altera Cyclone IV FPGA, 32 MB of SDRAM, 2 Kb EEPROM, 16 Mb serial configuration memory device, National Semiconductor 8-channel 12-bit A/D converter, Analog Devices 13-bit 3-axis accelerometer, built-in USB Blaster for FPGA programming, two push-buttons, eight user LEDs, four dip-switches, and expansion headers. Source code for the components on the FPGA board are also included.

Terasic Technologies DE0-Nano FPGA development and education board

DE0-Nano Development and Education Board Features

Altera Cyclone IV EP4CE22F17C6N FPGA

On-board USB-Blaster circuit for programming

Altera EPCS16 serial configuration device

Two 40-pin Headers (GPIOs) provides 72 I/O pins

Two 5V power pins, two 3.3V power pins and four ground pins

26-pin header provides 16 digital I/O pins and 8 analog input pins to connect to analog sensors

32MB SDRAM

2Kb I2C EEPROM

Eight green LEDs

Two debounced push-buttons

Four dip switches

ADI ADXL345 3-axis accelerometer with high resolution (13-bit)

National Semiconductor ADC128S022 8-Channel, 12-bit A/D Converter (50 ksps to 200 ksps)

On-board 50MHz clock oscillator

Power Supply: USB Type mini-AB port (5V), Two DC 5V pins of the GPIO headers (5V), 2-pin external power header (3.6-5.7V)

Source code for every component on board that enables users to quickly and easily gain an understanding of the basic design concepts

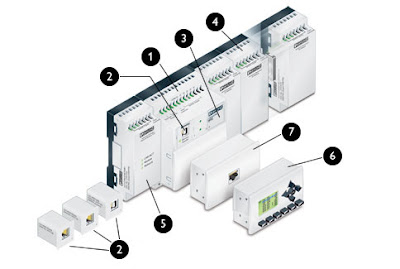

Nanoline - The smart, simple control system

Please make a selection from the different components below.

1. Base Units

2. Communications Option modules

3. Real time Clock

4. Expansion I/O Modules

5. Communications Expansion Modules (Ethernet and SMS Modem)

6. Operator Panel

7. Remote mounting for Operator Panel

Nano line Resource Center

NANO LINES ARE HAVING BELOW PROPERTIES:

Smart, simple, connected, flexible

Smart

The Nanoline is a smart, compact control system designed to perform many tasks automatically, saving time and preventing errors.

Simple

The Nanoline controllers are programmed using an intuitive flow chart programming language that requires no programming background to produce a working program. Relay ladder logic (RLL) is available as a second language to ease programming for users already familiar with RLL language.

Connected The Nanoline supports a new level of connectivity in its product class. Nanoline controls can be embedded into systems, monitored from a distance, or remotely controlled by a host computer, large PLC or advanced HMI.

Flexible

Select only the necessary project components with this easy-to-use, tightly-integrated, modular system.

Monday, July 25, 2011

Shape Memory NOKIA PHONES

In a highly ambitious materials development study commissioned by The Defense Advanced Research Projects Agency (DARPA), experiments conducted by materials scientists for the American military are successfully creating metals that can not only change shape upon the application of an energy field, but can autonomously ‘self-actuate’, producing intelligent alloys that have their own memory and motion capabilities.

DARPA identifies the research as the Development of Compact Hybrid Actuators based on Ferromagnetic Poly-crystal (Fe-Pd) material, & describes the product as “a robust compact actuator based on polycrystalline ferromagnetic shape memory alloy (FSMA) materials.“ Other possible smart materials technologies being explored for integration into military systems include shape memory alloys, piezoelectric actuators, magneto-rheological fluids and solids, self-healing polymers and coatings.

The goal is to develop and exhibit workable composite materials and processes to sustain the manufacture of multiple military morphing applications. The Military intends to develop a template prototype for improved function in vehicle bodies ready for integration with their existing hardware for operational use. In the process, DARPA are applying a specialized catalogue of smart materials technologies, such as shape memory polymers, self-actuating composites, and dynamic syntactic foams. They also employ smart materials, engineering design, fabrication, and other supporting technologies to meet the goals and requirements of the military industrial complex.

Called Iron-Palladium alloys, these metals possess super-elasticity & shape-shifting capabilities, augmented further by the integration of more ‘intelligent’

Nokia Shape memory phone

components into the alloy, allows it to generate its own energy field to reshape. The metal itself incorporates an ‘electromagnetic driving unit’ and a ‘position sensor with a central unit.’ The Fe-Pd spring actuator is just 15cm in length by a diameter of 3 cm, yet this spring will become an intelligent autonomous machine with a remarkable tensile strength for its own ‘shape memory’.

Optimized for best performance around one operating point & similar in architecture to biological systems, these new actuators are like individual elements arranged in parallel-series assemblies, but use very different building blocks. Upon the generation of an electric current or magnetic field these alloys will, with no moving parts, change shape & rapidly. They are termed ‘compact hybrid actuators’, or ‘living metals’ & are designed to mimic living systems in their versatility and dynamism through the integration of advanced nano-technologies. DARPA’s smart structures engineering team are focused on integrating multiple smart material technologies with conventional actuation mechanisms, and on developing realistic morphing structure concepts for theatre applications. The research will help define near-term morphing abilities, help identify the next enabling materials technologies necessary to round out structural morphing composites, and predict the exponential growth of morphing capabilities.

Shape memory car

With the use of combustible fuel sources, the small elements comprising the actuation system achieve high power and energy density, allowing efficient energy conversion via oscillatory and resonant processes. Rather than by valves or power transistors, the power produced is modulated at the individual element level, providing effective efficient power output with less input. Mass production methods via a use of modular architecture where many similar or identical elements are used, allows cost effective manufacture as well as economies of scale. This approach, characterized by the use of many elements systematically interconnected in terms of structure, physical effort, and information is termed Organismic Systems by the scientific community & incorporates the basic principles of nano-technology.

These metals built at the molecular level are essentially machines with complex internal systems & structures that mimic organic ones. The metal alloy actuators are essentially autonomous, the nano-machines incorporated into the metal alloys utilize energy sources at the ‘individual’ level & assign the material characteristics generally attributed to extraterrestrial craft. There are many magnetic anomalies reported by witnesses and researchers that ascribe certain attributes to this material, that have a connection with UFO technology. and a correlation between changing form and magnetic field effects appears to be an important consideration.

Shape memory wing foil

Their potential application for the U.S. military has driven them to funding a variety of related research programs exploring the full range of options proposed by private-sector aerospace consortiums including Boeing, M.I.T., Moog and Lockheed Martin in conjunction with several university departments in receipt of grants from the U.S. Military. The entire project is endorsed by the US Army Research Office, the Office Of Naval Research, NASA Langley Research Center, & the Space Operations Vehicle Technology Office, AFRL/VAS at Wright Patterson AFB.

Some of the projects being explored include: the research & development of assault vehicles with self-repairing armored shells that react like living organisms with noise cancellation capabilities to ‘cloak’ them on an auditory level; in-flight navigation, guidance and control systems for smart bombs that lie dormant, that can identify a target through face recognition; shape-changing bombers that transform into jet fighters, including morphing aeroforms in Unmanned Aerial Vehicles (UAVs) and fighter aircraft; advanced optical systems for satellite technology, as well as sonar-absorbing materials for submarines with respect to the sonar deductibility of torpedoes; & ‘exo-skeletons’ incorporating neural transmission technologies between the soldier’s brain waves and his living metal smart skin.

The power to drive the actuators is portable, and could be worn like a back-pack by soldiers. Like ‘nano-technology’ designed at a molecular level, the intelligent ‘biological’ actuators have purpose-built machines within them. Placed in the context of brain implants that can pick up neurological information directly, this information could then readily be transferred to the ‘morphing metal’ interface that will be capable of adapting to the complex commands delivered by the brain. other applications include the development of prosthetic limbs made of these alloys that receive direct instruction from the wearer’s brain, & behave like real limbs & muscles.

Nitinol invented by metallurgist William Buehler

Highly specialized privatized materials research companies, commissioned to develop this technology, in their design and engineering efforts will focus on integrating new adaptive materials technologies into standard composite armatures. CRG are developing a preliminary prototype design of an adaptive wing structure. By establishing a processing approach to fabrication, validating these fabrication processes to demonstrate a working segment of a morphing wing to prove feasibility, the company hopes to have a working integrated system of manufacture by project’s end. Design considerations for the adaptive wing include wing mass, primary structure, leading and trailing edges, airfoil balance, seamless skin, internal structure, actuation mechanisms, and environmental stability.

Aurora X-plane

These programs will establish the technology necessary to assemble deployable morphing aircraft and other innovative adaptive structure concepts vital to maintain military advantage. In addition to enhancing the aerospace industry’s system platform capabilities, this technology will also enhance the ability to broaden their system capabilities for multiple Department of Defense (DOD) applications planned in the near and far term. This advancement will improve performance for other current or future applications. The development of this technology from prototype to integration and manufacturing will demonstrate the superiority of the Military in the fields of research, development and materials innovation, as well as maintain funding.

DARPA identifies the research as the Development of Compact Hybrid Actuators based on Ferromagnetic Poly-crystal (Fe-Pd) material, & describes the product as “a robust compact actuator based on polycrystalline ferromagnetic shape memory alloy (FSMA) materials.“ Other possible smart materials technologies being explored for integration into military systems include shape memory alloys, piezoelectric actuators, magneto-rheological fluids and solids, self-healing polymers and coatings.

The goal is to develop and exhibit workable composite materials and processes to sustain the manufacture of multiple military morphing applications. The Military intends to develop a template prototype for improved function in vehicle bodies ready for integration with their existing hardware for operational use. In the process, DARPA are applying a specialized catalogue of smart materials technologies, such as shape memory polymers, self-actuating composites, and dynamic syntactic foams. They also employ smart materials, engineering design, fabrication, and other supporting technologies to meet the goals and requirements of the military industrial complex.

Called Iron-Palladium alloys, these metals possess super-elasticity & shape-shifting capabilities, augmented further by the integration of more ‘intelligent’

Nokia Shape memory phone

components into the alloy, allows it to generate its own energy field to reshape. The metal itself incorporates an ‘electromagnetic driving unit’ and a ‘position sensor with a central unit.’ The Fe-Pd spring actuator is just 15cm in length by a diameter of 3 cm, yet this spring will become an intelligent autonomous machine with a remarkable tensile strength for its own ‘shape memory’.

Optimized for best performance around one operating point & similar in architecture to biological systems, these new actuators are like individual elements arranged in parallel-series assemblies, but use very different building blocks. Upon the generation of an electric current or magnetic field these alloys will, with no moving parts, change shape & rapidly. They are termed ‘compact hybrid actuators’, or ‘living metals’ & are designed to mimic living systems in their versatility and dynamism through the integration of advanced nano-technologies. DARPA’s smart structures engineering team are focused on integrating multiple smart material technologies with conventional actuation mechanisms, and on developing realistic morphing structure concepts for theatre applications. The research will help define near-term morphing abilities, help identify the next enabling materials technologies necessary to round out structural morphing composites, and predict the exponential growth of morphing capabilities.

Shape memory car

With the use of combustible fuel sources, the small elements comprising the actuation system achieve high power and energy density, allowing efficient energy conversion via oscillatory and resonant processes. Rather than by valves or power transistors, the power produced is modulated at the individual element level, providing effective efficient power output with less input. Mass production methods via a use of modular architecture where many similar or identical elements are used, allows cost effective manufacture as well as economies of scale. This approach, characterized by the use of many elements systematically interconnected in terms of structure, physical effort, and information is termed Organismic Systems by the scientific community & incorporates the basic principles of nano-technology.

These metals built at the molecular level are essentially machines with complex internal systems & structures that mimic organic ones. The metal alloy actuators are essentially autonomous, the nano-machines incorporated into the metal alloys utilize energy sources at the ‘individual’ level & assign the material characteristics generally attributed to extraterrestrial craft. There are many magnetic anomalies reported by witnesses and researchers that ascribe certain attributes to this material, that have a connection with UFO technology. and a correlation between changing form and magnetic field effects appears to be an important consideration.

Shape memory wing foil

Their potential application for the U.S. military has driven them to funding a variety of related research programs exploring the full range of options proposed by private-sector aerospace consortiums including Boeing, M.I.T., Moog and Lockheed Martin in conjunction with several university departments in receipt of grants from the U.S. Military. The entire project is endorsed by the US Army Research Office, the Office Of Naval Research, NASA Langley Research Center, & the Space Operations Vehicle Technology Office, AFRL/VAS at Wright Patterson AFB.

Some of the projects being explored include: the research & development of assault vehicles with self-repairing armored shells that react like living organisms with noise cancellation capabilities to ‘cloak’ them on an auditory level; in-flight navigation, guidance and control systems for smart bombs that lie dormant, that can identify a target through face recognition; shape-changing bombers that transform into jet fighters, including morphing aeroforms in Unmanned Aerial Vehicles (UAVs) and fighter aircraft; advanced optical systems for satellite technology, as well as sonar-absorbing materials for submarines with respect to the sonar deductibility of torpedoes; & ‘exo-skeletons’ incorporating neural transmission technologies between the soldier’s brain waves and his living metal smart skin.

The power to drive the actuators is portable, and could be worn like a back-pack by soldiers. Like ‘nano-technology’ designed at a molecular level, the intelligent ‘biological’ actuators have purpose-built machines within them. Placed in the context of brain implants that can pick up neurological information directly, this information could then readily be transferred to the ‘morphing metal’ interface that will be capable of adapting to the complex commands delivered by the brain. other applications include the development of prosthetic limbs made of these alloys that receive direct instruction from the wearer’s brain, & behave like real limbs & muscles.

Nitinol invented by metallurgist William Buehler

Highly specialized privatized materials research companies, commissioned to develop this technology, in their design and engineering efforts will focus on integrating new adaptive materials technologies into standard composite armatures. CRG are developing a preliminary prototype design of an adaptive wing structure. By establishing a processing approach to fabrication, validating these fabrication processes to demonstrate a working segment of a morphing wing to prove feasibility, the company hopes to have a working integrated system of manufacture by project’s end. Design considerations for the adaptive wing include wing mass, primary structure, leading and trailing edges, airfoil balance, seamless skin, internal structure, actuation mechanisms, and environmental stability.

Aurora X-plane

These programs will establish the technology necessary to assemble deployable morphing aircraft and other innovative adaptive structure concepts vital to maintain military advantage. In addition to enhancing the aerospace industry’s system platform capabilities, this technology will also enhance the ability to broaden their system capabilities for multiple Department of Defense (DOD) applications planned in the near and far term. This advancement will improve performance for other current or future applications. The development of this technology from prototype to integration and manufacturing will demonstrate the superiority of the Military in the fields of research, development and materials innovation, as well as maintain funding.

Nano-engineered Bug electric car allows safe, sustainable and economical trave

Conceived by designer Ricardo Fedrizzi, the “Bug” is an agile urban micro-car for two people that allows safe, brisk and sustainable commutation on city roads. Touting an aerodynamic shape, with fluid curves, which gives greater efficiency by increasing the autonomy, the new electric car by the Brazilian designer focuses mainly on maximum weight reduction, promoting economy and performance. The micro-car replaces the glass windows and windshield with much lighter and resilient polycarbonate to ensure complete safety. Made in recyclable and renewable materials, such as polymers with a load of vegetable fiber, the Bug comes with both light and tough alloys, designed using nanotechnology, to allow a safe and an environmentally responsible traveling, and that too at an affordable price.

[Thanks Ricardo]

More Pictures -> http://www.thedesignblog.org/entry/nano-engineered-bug-electric-car-allows-safe-sustainable-and-economical-travel/

[Thanks Ricardo]

More Pictures -> http://www.thedesignblog.org/entry/nano-engineered-bug-electric-car-allows-safe-sustainable-and-economical-travel/

Subscribe to:

Posts

(

Atom

)